Driving innovation and ensuring excellence through rigorous R&D and quality control practices.

DURABILITY OF OUR COATINGS

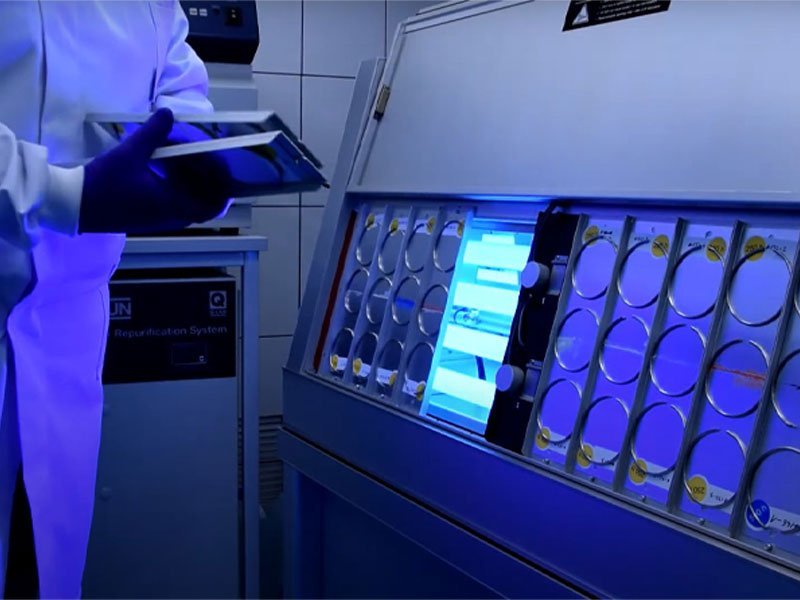

We’re proud of our commitment to always improving our products. We make them better by improving our manufacturing processes and the durability of our coatings. To test our coatings, we use different methods. We use UV-A and UV-B chambers to see how well they resist UV rays. We also use acetic salt spray chambers (Q-FOG) to test their resistance to corrosion. Besides that, we use other instruments like the tensile tester, taber abraser, analytical balance, and rapid deformation tester. These help us evaluate properties like wear resistance, deformation, and mechanical strength. Using these comprehensive tests ensures that our products meet the highest quality and durability standards.

A CULTURE THAT FOCUSES ON CONTINUOUS IMPROVEMENT

Our dedicated team in R&D along with our paint supplier are constantly at the forefront of innovation, collaboratively driving improvements and pushing the boundaries of what’s possible. With their unwavering dedication and expertise, they are always exploring new ideas, technologies, and methodologies to enhance our products. Through extensive research, experimentation, and collaboration, we strive to stay ahead of the curve and deliver cutting-edge solutions that address the evolving needs of our customers.

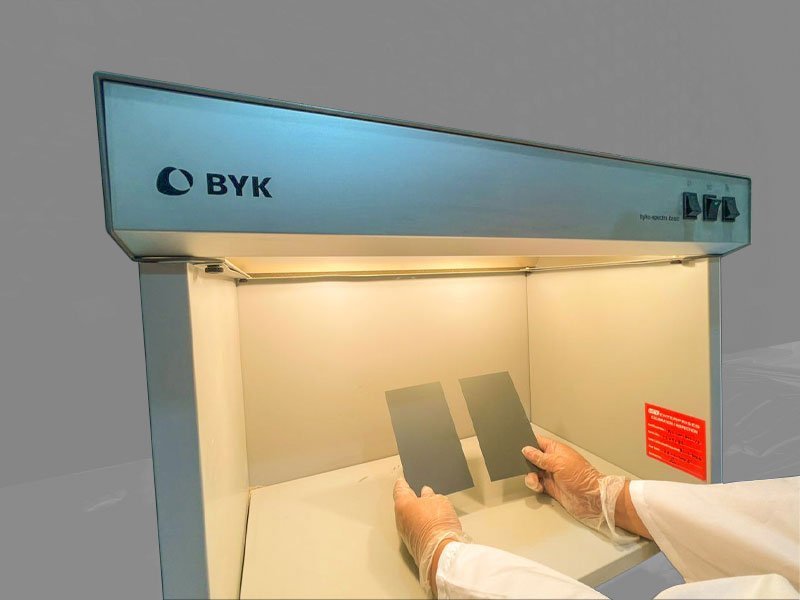

Ensuring Quality with Advanced Inspection Tools

We emphasizes the importance of thorough and meticulous inspection on our coating lines to ensure that quality is met with the highest standards. We have equipped our lines with various instrument such as:

– Smart vision system: High speed CCD & Lens utilized to inspect the surface in case of defects.

– Glossmeter : to measure coating glossiness

– Isoscope: to measure coating thickness

– XRF spectrometry: to measure coating weight of the surface treatment

– Spectrophotometer: to measure the colour shade

Zain One was born with a bold vision: to establish itself as the international benchmark in coating technologies of Aluminum coils.

Our approach is centered around collaboration, transparency, and trust, fostering strong partnerships with our valued clients, suppliers, shareholders, and the communities we impact.